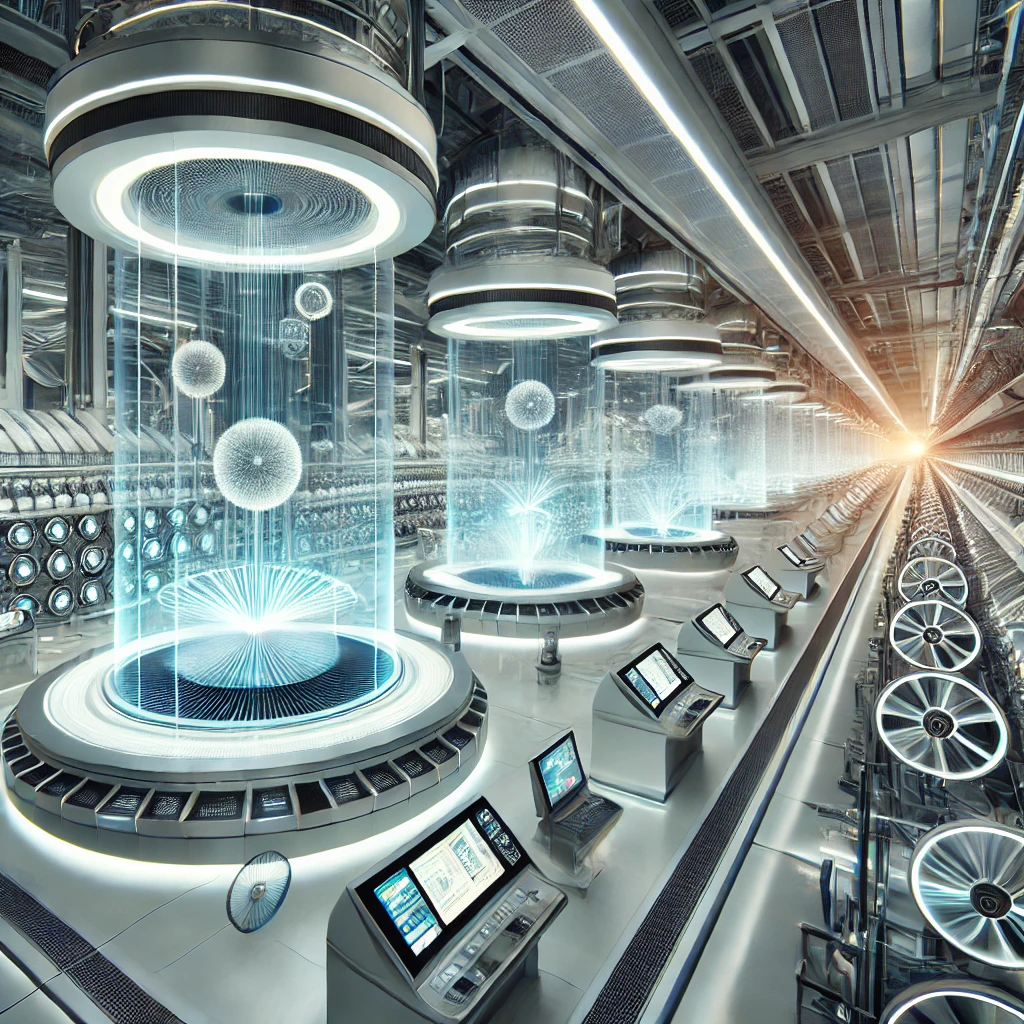

In the textile industry, staying at the forefront of technology is essential to compete against imported products. Investing in state-of-the-art machinery provides a range of key benefits that not only enhance productivity but also directly impact production costs and environmental sustainability.

Cost Reduction and Increased Efficiency

Modern machines are designed to be more efficient in terms of energy consumption, material usage, and production times. Thanks to advanced automation, it is possible to produce more in less time, reducing labor costs and enabling textile companies to increase their production capacity without significantly increasing resources. Additionally, these machines offer greater durability, resulting in less downtime due to maintenance or breakdowns, further reducing long-term costs.

Another advantage is that the latest machines can process a wide variety of materials with greater precision, enabling more diversified and higher-quality production. This results in more competitive final products, helping local companies to better compete with imported goods.

Impacto Ambiental y Sostenibilidad

One of the greatest challenges facing the textile industry today is sustainability. State-of-the-art machines are designed to minimize environmental impact. For instance, many are equipped with systems that significantly reduce water and energy consumption, which is especially critical in processes like dyeing. Some machines also enable the reuse of resources such as water or heat generated during production, contributing to a more eco-friendly manufacturing process.

By utilizing fewer natural resources and generating less waste, companies not only reduce their operational costs but also comply with increasingly stringent sustainability and environmental responsibility regulations. This approach not only benefits the planet but also enhances the company's reputation among consumers, who increasingly value environmentally friendly products. Furthermore, adopting sustainable practices positions businesses as forward-thinking leaders in their industry, appealing to a growing market segment that prioritizes eco-consciousness.

Comparison with Used Machinery

Today, we understand that investing in new textile machinery may seem costly at first, but when compared to used machinery, it often proves to be more economical in the long run. New machines not only provide cutting-edge technology but also come with warranties, typically covering 12 months, offering peace of mind in case of technical issues. In contrast, used machinery lacks warranty coverage and often requires significant investment for setup or repairs, which can substantially increase total costs.

Thanks to our office in China, we are able to Silqui-Tex International we have the advantage of negotiating directly with manufacturers, allowing us to offer high-quality machinery with top-tier after-sales service. Unlike many sellers in Asia who simply place their brand on machines made by third parties, we work directly with manufacturers, ensuring our customers receive the best product and support.

Competitiveness and Future

In a globalized world, competition is fierce. To stay ahead, companies must produce at competitive costs without compromising quality. State-of-the-art textile machinery not only ensures efficient and high-quality production but also enables businesses to adapt to changing market trends, such as the growing demand for sustainable or customized products.

In conclusion, investing in modern machinery is not just about staying competitive; it is a key strategy for reducing costs, improving efficiency, and simultaneously protecting the environment. At Silqui-Tex International, we understand the importance of staying at the forefront of technology and offer the best solutions in state-of-the-art machinery, enabling textile companies to compete successfully in a global market.

Silqui-Tex is ready to supply all the needs of its customers.