SILQUI TEX

MACHINERY

At Silqui-Tex SRL, we lead the Argentine market in textile machinery sales, standing out for offering high-quality equipment that meets the industry's highest demands. We offer a wide selection of machinery in excellent condition, ready for production, and designed to maximize efficiency at every stage of the textile process.

Thanks to the trust inspired by our products and the excellence of our after-sales services, we have established ourselves as the preferred supplier for leading spinning mills and textile companies across the country. Our range includes:

Every machine we sell undergoes a rigorous inspection and reconditioning process to ensure optimal performance from day one. This commitment to quality allows us to guarantee equipment that not only maximizes productivity but also adapts to the specific needs of our clients.

In addition, our after-sales network provides specialized technical support, original spare parts, and ongoing maintenance, extending the equipment's lifespan and ensuring uninterrupted operations.

At Silqui-Tex, our commitment is to provide comprehensive and reliable solutions backed by over 40 years of experience in the textile sector. With the addition of new lines of machinery, we reaffirm our dedication to offering advanced and sustainable technology that enhances the competitiveness of our clients in an ever-evolving market.

SPARE PARTS

As is well known, factories aim to minimize their operating costs, which often involves maintaining a limited inventory of spare parts for their machinery. In response to this need, Silqui-Tex has become a reliable warehouse for spare parts and accessories, providing our clients with everything they need to keep their operations running smoothly and without interruptions.

Our extensive inventory includes spare parts and accessories for a wide range of textile machines, ensuring immediate availability and minimizing downtime for our clients.

Silqui-Tex supplies factories across the country and has also expanded its operations to other South American countries, including Brazil, Paraguay, Chile, Uruguay, and Bolivia, as well as to global markets.

Our services:

Thanks to our infrastructure and distribution network, Silqui-Tex ensures that our clients always have access to the spare parts and accessories they need, enabling them to operate at maximum efficiency while minimizing downtime.

Our mission is to be the trusted partner for textile factories, not only in Argentina but also around the world, providing comprehensive, high-quality solutions that support the growth and sustainability of their operations.

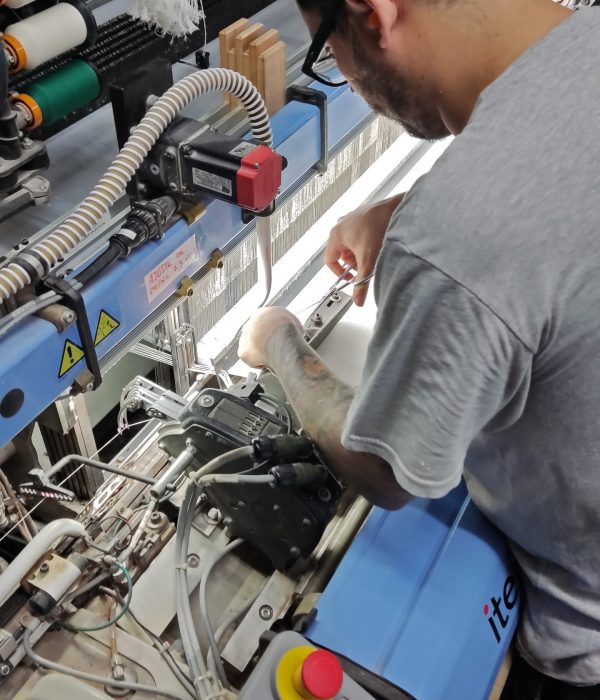

At Silqui-Tex, we offer specialized technical services for the assembly and preventive maintenance of textile machinery. We are trusted by numerous leading companies in the industry, having worked in some of the most prominent factories in the country. Our team of assemblers is highly trained and specialized in every area of the textile production line, including:

Opening and Cleaning: Installation and maintenance of equipment for the initial preparation of fibers.

- Carding: Assembly and adjustment of carding machines to optimize fiber alignment and opening.

- Open End: Setup and maintenance of Open End spinning equipment, ensuring high productivity and yarn quality.

- Winding: Installation and calibration of winding machines to ensure precise and uniform yarn winding.

In addition, we carry out technical upgrades on various machines, such as:

- Installation of Frequency Inverters: Implementation of frequency inverters in carding machines, roving frames, ring spinning machines, and Open End systems. This technology enables electronic regulation of speed and yarn count, eliminating the need for mechanical adjustments to pulleys and gears.

These modifications not only enhance operational efficiency but also provide greater flexibility and control over production processes. Frequency inverters enable precise, real-time adjustments, optimizing machine performance and adapting seamlessly to specific production requirements. This advanced technology ensures a smoother operation, reduces downtime, and enhances overall productivity.

At Silqui-Tex, we are dedicated to providing advanced and customized technical solutions, ensuring the optimal performance of your equipment while meeting the specific demands of each client in the textile industry.

SPECIALIZED SERVICES BY SILQUI-TEX

At Silqui-Tex International, we understand the importance of maintaining operational efficiency in spinning mills. That is why we have developed a range of specialized services tailored to meet the specific technical needs of this sector. Our highly trained team and advanced technology ensure top-quality performance in the following processes:

Additionally, we provide rubber cylinders specifically designed for covering, ensuring optimal integration and superior performance in textile machinery.

With our technical expertise and tailored solutions, Silqui-Tex International positions itself as a strategic partner for spinning mills, guaranteeing continuous and efficient operations in the textile industry.

Copyright © 2023 Silqui-Tex

Escribinos!